A Conversation with 2 GOTS Approved Consultants

What is your role as a GOTS Certified Consultant?

Katharina Schaus: I see my most important role as a "mediator" between the standard setter (GOTS), the standard users (traders, producer, manufacturers) and the certification bodies as well as accreditation bodies. I very much hope to be able to encourage and guide the requirements, processes, further developments for all involved "parties" in the GOTS-system as best as possible. Since I understand GOTS from all angles, I see myself in a position to support GOTS in its further development/improvement, to advise companies in their preparation for certification, but equally to accompany certification bodies in their accreditation and business development.

Ely Battalen: I work with brands and manufacturers in a two-phase process. First, I analyse if the client is prepared to pass the audit, and then secondly, I work with the client to implement procedures, processes, etc., needed to bring them into compliance.

What might a company or brand need to do or think about before they can achieve (apply for?) certification?

KS: Companies need to be clear about their sustainability goals and consider whether GOTS certification is a suitable instrument to implement their own goals. They need to study the standard/requirements in order to be able to determine whether they can comply with them at all. That certification means a lot of documentation is not clear to many. Nor that certification means independent quality assurance and that a fair budget must be available for this service provided by the certification bodies. On the other hand, certificates cannot simply be “bought”, no - they have to be elaborated. Thus, it must also be conscious that time and willingness for documentation and adjustments is necessary.

EB: Being certified to GOTS is not only about organic fibre, but the standard covers social and environmental aspects, as well as the need for a high level of inventory control.

Do you have any advice for a business that is considering getting certified or introducing certified products?

KS: It requires know-how to get certified or to include certified products in the portfolio. This know-how must come from somewhere. The companies can try to build it up effortfully on ¬their own. Or they have the option to call in us approved consultants as supporters, which makes the processes and implementation more profound and much easier. The GOTS system is demanding and thus there is plenty of potential for errors with possibly result in unpleasant consequences. To avoid mistakes and associated consequences, I can highly recommend the involvement of the consultants. In addition, I think it is very important that companies strive for certification out of conviction and not because pressure and demands are imposed from outside. Then, they will make a successful use of certification and their certified products.

EB: Contact a certified consultant!

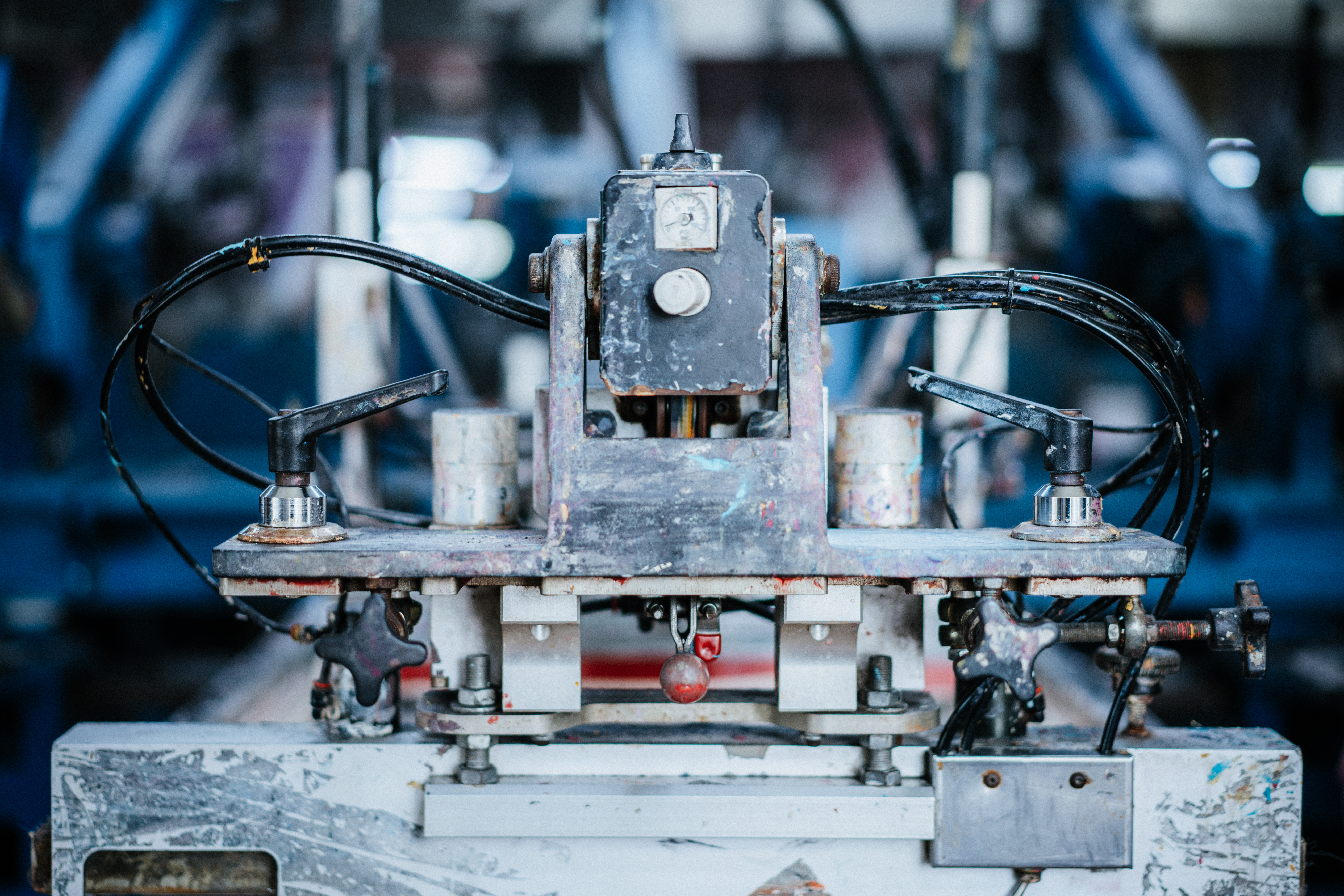

One source of change in the textile processing industry is the constant improvement of the science and technology involved. What are some of the significant changes you’ve seen? How do those changes impact certification?

EB: One shift I’ve noticed recently is the replacement of workers with technology/robotics. This can mean the employment of fewer workers but also increased safety.

KS: I find the possibility of DNA tagging on cotton fibres a very groundbreaking development, especially in light of issues such as GMO contamination and organic fraud. This technology offers a solution to these problems and at the same time an innovative traceability tool. Herewith a method is available for the certification, which allows to secure and trace back some requirements even better, which is not used obligatorily until now. If all organic cotton were marked with the DNA tracers, the assurance of origin would be greatly improved and there would be reliable data on available quantities of certified fiber and materials, which currently do not exist.

But another, not technical related issue will have a significant impact on certification. There will be a flood of new laws/regulations especially for the textile industry, which have to be implemented already in the next years - supply chain law / due diligence law, EU strategy for sustainable and recyclable textiles in Europe, new waste regulations, etc. Certification must also be able to provide evidence of compliance with these laws/regulations. If this succeeds, then certification will continue to gain enormously in importance and can therefore expect a large increase of demand in the coming years.

What are some misconceptions about certification and what should people know?

KS: The standards / requirements apply equally to all companies, whether in Asia or in Europe. No exception or individual adjustment can or will be made for anyone individually. Furthermore, the job of the certification bodies is to verify compliance with all requirements, but not to develop the standards or make adjustments for individuals. In other words, this means, certification bodies are not in the position to offer consulting services as well as sourcing services. But many companies expect these kind of services from certifiers and are annoyed when they do not receive advice. This is exactly why it made sense for GOTS to integrate independent, approved consultants into its system. In my opinion, this significantly improves implementation and further development. It also makes companies feel satisfied and comforted if they also have a resource for guidance.

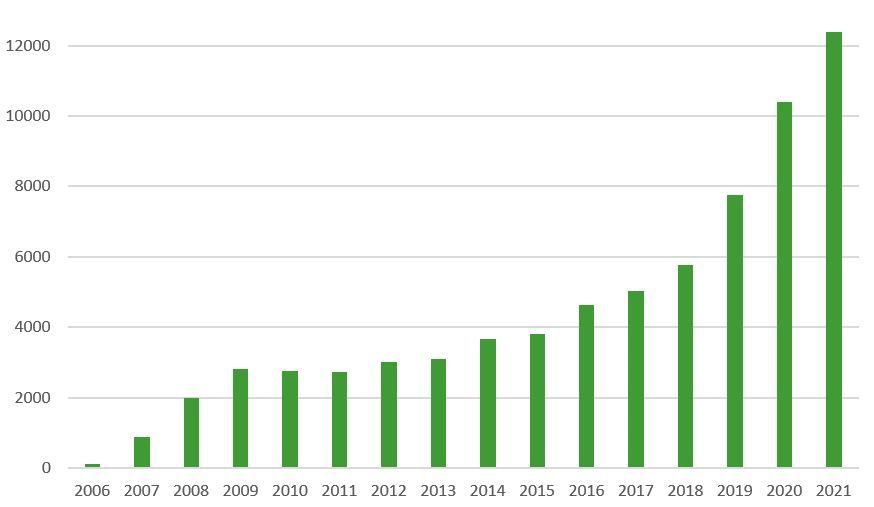

Certification is more credible than self-statements. In addition, GOTS as an independent certification system is by far less expensive than setting up an own sustainability program and/or sustainable seal. GOTS is an excellently established independent standard with a number of benefits. Quite reasonably, GOTS is called the most recommendable standard in the field of natural fibers. GOTS has now grown to over 12,000 certified companies, because this standard managed to harmonize with numerous other schemes in the early 2000s. The strength of GOTS is that the requirements are set across the entire value chain, covering social and environmental aspects with high standards. Of course, a high standard is not always easy to be achieved, but I am pleased when many companies approach me so that I can support them in the implementation and clarification of all concerns.

EB: A frequent misconception is a client believing that by having a Transaction Certificate from their supplier, they are abiding by the standard and can then make label claims.

More information about Katharina and Ely can be found at their websites:

Katharina Schaus website - http://www.itfits.de

Ely Battalen website - www.ewbconsultingllc.com

Case Study: Armstrong Knitting Mills

GOTS Case Study:

Armstrong Knitting Mills

Weaving Sustainability into Business with Armstrong Group

Armstrong Knitting Mills, a textile factory in India that’s been in operation since 1969, is a pioneer in sustainable textiles and business in the industry and is known for its commitment to sustainability, social responsibility, and innovation.

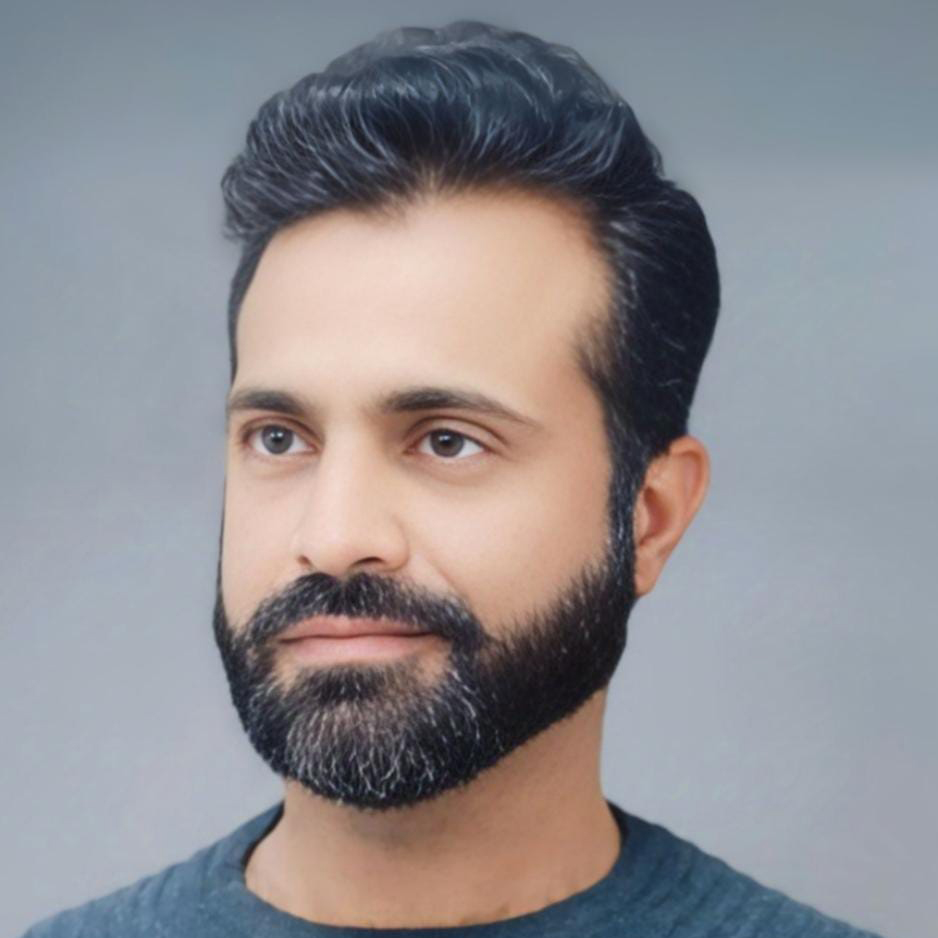

From Farm to Fashion

From Farm to Fashion

Armstrong Group boasts a vertical setup that encompasses the entire textile production process, from sourcing quality cotton to creating impeccable garments. Sustainability is the cornerstone of their operations, and it is evident in multiple aspects of their business, including:

Armstrong has invested substantially in renewable energy sources, harnessing wind and solar power. They generate over 18.5 megawatts from windmills and 9.234 megawatts from solar energy annually, which is enough to ensure that their operations are powered entirely by green energy. This not only makes Armstrong a net-zero carbon emission factory but also reduces 25 million kilograms of CO2 emissions annually.

Recognising the threat of plastic waste, Armstrong has embraced sustainability by using post-consumer recycled PET polyester throughout operations. In the past ten years, this effort has saved 60 million plastic bottles from ending up in landfills.

Green Planet

Armstrong's commitment to making the planet greener is evident in its extensive tree-planting initiatives, which have seen over 5,200 trees planted in its region over the last five years. It also collects and stores millions of litres of rainwater for various purposes.

Fair Trade Premium:

Armstrong supports local farmers with fair-trade premiums, totalling around $1.6 million over a decade. These premiums contribute to improving the living standards of farmers through a number of programs.

Employee Benefits

Employees are at the heart of Armstrong's success, and the company tries to provide as many opportunities for the well-being of its workers as possible. That includes a safe and hygienic work environment, competitive pay, free transport, healthcare, and an on-site childcare facility.

Armstrong extends its impact beyond its operations by offering free training programs to those interested in the garment industry. These training opportunities, guided by experts, aim to develop a skilled and knowledgeable workforce, benefiting not only Armstrong but also other manufacturers in the region.

GOTS certification underscores Armstrong's adherence to eco-friendly manufacturing practices. It assures consumers that the textiles are produced using natural resources thoughtfully and responsibly, aligning with Armstrong's goal of safeguarding the environment.

Case Study: DM Drogerie Markt

GOTS Case Study:

DM Drogerie Markt

Founded in 1973 by Prof. Götz W. Werner in Karlsruhe, dm-drogerie markt has evolved into Germany's most profitable drugstore chain, boasting a workforce of over 46,000 employees. With a network of 2,000+ stores across Germany, the company welcomes up to two million customers daily, offering a wide array of products. Its online shop offers over 18,000 items.

Core Commitment to Sustainability

Sustainability lies at the heart of dm’s ethos, ensuring not only economic but ecological, societal, and cultural sustainability. Christoph Werner, Chairman of the dm Management Board, encapsulates the company’s vision: "Our vision at dm is to help make our world, our society, and our lives a little better through our actions." Kerstin Erbe, dm Managing Director for Product Management, adds, "Acting sustainably means, for us, acting in harmony with nature, for the benefit of each other, as well as for innovation and progress."

GOTS Certification

dm’s early adoption of GOTS-certified products made from organic cotton in their children's clothing section, resulting in 96% of ALANA children's textiles being GOTS certified today, exemplifies its commitment to sustainable practices. GOTS certification seamlessly aligns with the company's comprehensive sustainability perspective, emphasising social and ecological dimensions, reinforced by its rigorous inspection processes, solidifying its status as a reputable and sustainable standard.

Tangible Sustainability: Recycled Hangers

GOTS requirements motivated dm to adopt recycled hangers for ALANA textiles. These hangers, crafted from grass fibre plastic, operate within a circular economy model, experiencing multiple use cycles. At the end of their life, damaged hangers are entirely recycled into new ones, reinforcing the sustainability loop.

Expanding for the Future

dm’s commitment to GOTS certification extends beyond ALANA children's textiles, encompassing various product categories such as Fascino hosiery, ebelin towels, Jessa tampons, and Profissimo dishcloths, further demonstrating its dedication to sustainable and responsible practices.

dm’s unwavering sustainability commitment, epitomised by GOTS certification, shapes a narrative of eco-consciousness and social responsibility. Its expansion into diverse sustainable product offerings and the practice of a circular economy underpins the company’s role as a pioneering force in fostering a more sustainable future.

Case Study: FC St Pauli

GOTS Case Study:

FC St. Pauli

FAIR PLAY ON AND OFF THE FOOTBALL FIELD!

Introduction

In the heart of the vibrant St. Pauli district in Hamburg, there is a football club that defies outdated conventions - the Football Club St. Pauli 1910 e.V., affectionately known as FC St. Pauli. But this is no ordinary football club; it is a source of social culture and a champion of sustainability, proudly holding its GOTS certification.

A History of Perseverance

Since its founding in 1910, FC St. Pauli has experienced it all - promotions and relegations on the football field. But its impact goes far beyond sports. In the 80s, it underwent a transformation and became a cultural phenomenon, shaped by left-wing politics, social activism, and its iconic skull emblem.

Confronted with the global challenges that concern us all, such as climate change, FC St. Pauli leads by example and lives sustainability! It's not just about being environmentally friendly, but also about reducing energy consumption, minimising resource use, and upholding human rights for the benefit of all.

For FC St. Pauli, sustainability is more than just a word - it's a way of life. This creed is built upon five central principles deeply embedded in the club:

Fairness: Throughout the production and supply chain, FC St. Pauli guarantees fairness. This means appropriate wages, dignified working conditions, and a strict “Never!“ to child labour.

Ecology: Environmental responsibility is paramount. The club emblem is proudly printed on organic cotton, recycled materials, and organic fabrics in functional clothing.

Economic sustainability: Striking a balance between sustainability and financial stability is crucial. The revenue from merchandise directly supports sports and social activities without driving up prices.

Local ties: FC St. Pauli passionately supports local initiatives, whether through fan projects or aid to the Hamburg club scene in difficult times. The club is deeply rooted in its neighbourhood and demonstrates teamwork off the football field as well.

Diversity: Diversity is a must-have! FC St. Pauli's products are increasingly gender-neutral and offer a variety of fits and styles to ensure everyone feels welcome. FC St. Pauli is not just a football club; it is a movement for a better and more sustainable world.

The Sustainable Football Experience – Not an Offside Situation Anymore:

The Sustainable Football Experience – Not an Offside Situation Anymore:

What set the ball rolling? A 17-year-old member's proposal to implement sustainability in merchandise production during the general assembly led to prompt action. FC St. Pauli responded by introducing a line of GOTS-certified merchandise products and is still applying these principles to more and more products, including its jerseys. Now, a significant portion of cotton textiles is GOTS-certified – and FC St. Pauli is the only football club in the world to be a member of the Fair Wear Foundation.

Starting from the 2021/22 season, FC St. Pauli, in collaboration with DIIY, designed the jerseys and team sport collection of the professional team. This has led to special designs that pay tribute to the club's values. For example, the third jersey of the 2022/23 season is inspired by local graffiti artist OZ, honours his art, and contributes to the upkeep of his grave through donations from parts of the sales proceeds, in line with FC St. Pauli's focus on counterculture and community.

FC St. Pauli's dedication to sustainability and GOTS certification extends far beyond the football field. The club recognises the immense social significance of football and uses it as a platform to promote sustainability and inspire others to follow their example. This journey is a shining example for the football community, showing that fair treatment on and off the field deserves green thumbs up! FC St. Pauli is not just a football club; it is a movement for a better, more inclusive, and sustainable world.

Case Study: Frugi

GOTS Case Study:

Frugi

Founded by new parents in 2004, Frugi, previously known as Cut4Cloth, has grown to be the UK's premier ethical and organic children's clothing brand. With a presence in over 550 retailers across 30 countries, the company is dedicated to showcasing that superior design, strong ethics, and passionate individuals can be transformative. Its journey involves the use of organic cotton from trusted farmers, recycled plastic bottles for outerwear, and a relentless pursuit of innovation, all aimed at leaving a positive mark on the world.

Case Study: Givachoice

GOTS Case Study:

GIVEACHOICE

Givachoice, a manufacturer of the world’s most renowned brands, remains unwavering in its commitment to shaping a more eco-conscious future.

By prioritising the reduction of environmental impact and championing ethical values and sound management practices in the fashion industry, the company's sustainability policy strives to safeguard both the environment and the well-being of future generations.

For Givachoice, sustainability is life!

Case Study: Hayleys Fabric

GOTS Case Study:

Hayleys Fabric

Pioneering Sustainable Textiles in Sri Lanka

Since its inception in 1992, Hayleys Fabric has emerged as a trailblazer in the textile industry, renowned for its unwavering commitment to sustainability. With GOTS certification earned in 2014, this Sri Lankan manufacturing powerhouse has become a beacon of responsible textile practices, setting a new standard for environmental stewardship, fair labour practices, and innovation.

Company Snapshot

Hayleys Fabric: Neboda, Sri Lanka

In operation: since 1992

GOTS-certified: since 2014

Employees: 3088

Output: 3 million-plus metres of fabric per month

Annual turnover: 72 Million USD

Leading the Sustainable Charge

Hayleys Fabric's path to sustainability lies at the company’s core. Sustainability and eco-friendly production, along with a commitment to innovation, form the fundamental principles that underpin every aspect of operations. From water and energy conservation to the creative transformation of waste into value-added products, Hayleys Fabric leaves no stone unturned in its quest to minimise its environmental footprint.

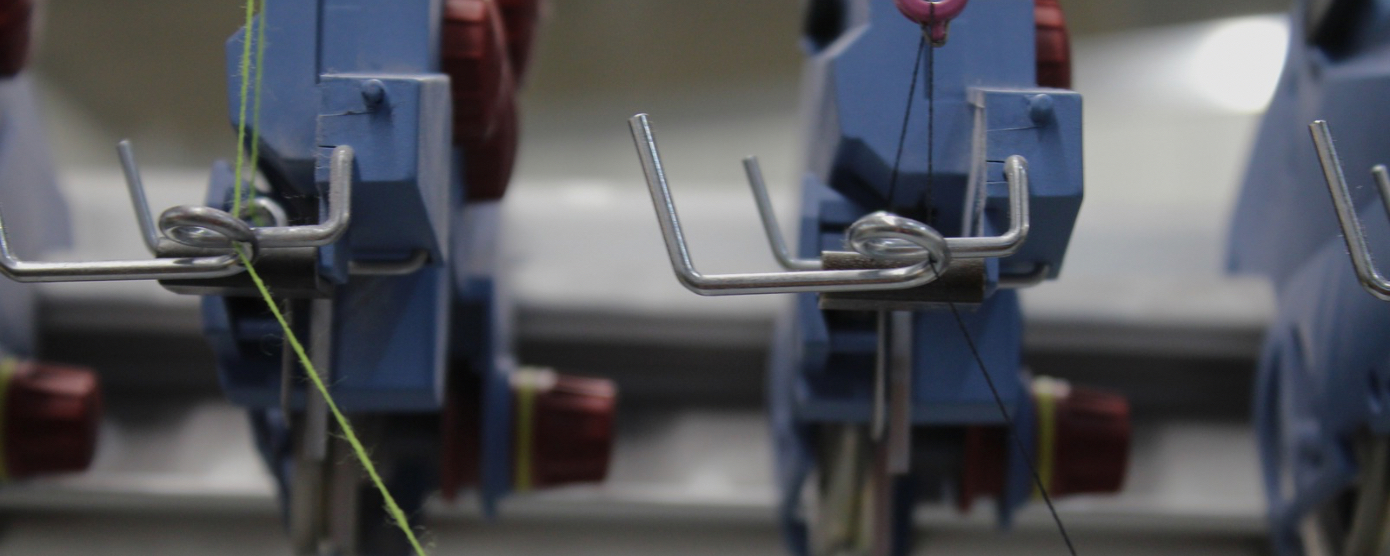

A testament to this commitment is Sri Lanka's largest single solar roof adorning its facility, generating 20 percent of the company's energy and reducing its carbon footprint by 15 percent. Its comprehensive textile processes span knitting, dyeing, printing, brushing, sueding, and finishing, offering a diverse portfolio of fabrics. Notably, the company has developed its own brand of fabric through its Innovation Centre, showcasing its prowess in sustainable textile solutions.

GOTS Certification: A Symbol of Dedication

For Hayleys Fabric, GOTS certification is more than a badge; it's a declaration of values. MD/CEO Rohan Goonetilleke passionately states, ‘GOTS reflects our unwavering commitment to responsible textile practices, ensuring our products meet the highest environmental and social standards’. GOTS certification has also unlocked enhanced market access, ushering in a culture of continuous improvement and innovation while showcasing adherence to regulatory standards. Like all GOTS Certified Entities, Hayleys Fabric has optimised its processes to reduce waste and increase energy efficiency, along with meeting the robust guidelines for social responsibility. GOTS certification helps Hayleys Fabric show its customers that the company takes sustainability seriously, Mr. Goonetilleke says: ‘This certification resonates with our dedication to sustainable sourcing, organic materials, and ethical production. It assures our customers that our fabrics are not only of superior quality but also crafted with utmost care for the planet and its people. GOTS certification serves as a testament to our unwavering dedication to responsible practices, fostering trust and transparency in our industry’.

But it's not just about compliance; Hayleys Fabric goes beyond. A green belt and biodiversity wetland park adjacent to the facility illustrate the company’s dedication to environmental stewardship. This sanctuary is home to nearly 300 species of flora and fauna, serving as an educational and research hub for local schools and universities. Its support for the restoration of endangered Sri Lankan forest plants and an in-house organic farm further exemplifies its commitment to the planet.

Transforming the Industry

Hayleys Fabric's GOTS certification has catalysed a transformation towards environmental stewardship, fair labour practices, and transparency across the value chain. The rigorous third-party certification process assures consumers that the strict GOTS requirements are met, empowering them to make informed choices that contribute to the growth of the global organic textile market.

Yearly audits and continuous improvement efforts drive creative problem-solving throughout the business. Notably, Hayleys Fabric has harnessed its innovation to develop sustainable products, including a mahogany dye from furniture waste and a black dye from its biomass waste.

A Future Aligned with Sustainability

GOTS certification has solidified Hayleys Fabric’s commitment to sustainability, attracted environmentally conscious clientele and reinforced the company’s strong ethos of ecological and socially responsible operations. As Head of Sustainability & Sustainable Innovations, Leonie Vaas aptly summarises, ‘This recognition has elevated our standing, drawn in environmentally conscious clientele, and emphasised our dedication to an eco-friendlier and more responsible textile sector’.

With its rich history, innovative spirit, and steadfast commitment to sustainability, Hayleys Fabric is not just a GOTS-certified company; it's a pioneering force reshaping the future of textiles for the better.

Case Study: JAN 'N JUNE

GOTS Case Study:

JAN 'N JUNE

Founded in 2014 by German designers Anna and Jula, JAN 'N JUNE is a Hamburg-based fashion company that embodies the fusion of fashion and sustainability. The company was born out of the necessity for sustainable fashion, and its ethos intertwines sustainability into every facet of its operations. This shift in societal awareness has not only fueled JAN 'N JUNE's growth but also cemented its status as a prominent sustainable fashion brand. The company's mission is clear: to demonstrate that fashion can be both stylish and sustainable.

GOTS Certification

The decision to obtain GOTS organic certification was a significant milestone for JAN 'N JUNE. It was a testament to the company’s unwavering commitment to ethical production and eco-conscious materials. JAN 'N JUNE recognised the importance of GOTS certification in fostering transparency and credibility in the fashion industry.

Holistic Sustainability

JAN 'N JUNE's commitment to sustainability extends throughout the business. The brand's ethos centres around the belief that fashion and sustainability can seamlessly coexist. The company takes pride in producing garments fairly in Portugal and Poland, using sustainable materials like organic cotton, recycled polyester, and lyocell. These choices reflect JAN 'N JUNE's unwavering dedication to ethical practices and eco-conscious fashion, encompassing a circular economy, waste reduction, responsible consumption, and creative approaches to repurposing fabric offcuts.

Resilience and the Road Ahead

The journey of JAN 'N JUNE has been marked by ups and downs, with the COVID-19 pandemic adding its own set of challenges. However, what the company takes the most pride in is its unwavering commitment to sustainability, its ability to adapt, and its solution-driven approach in the face of adversity. This resilience would not have been possible without a dedicated and hardworking team.

Case Study: LangerChen

GOTS Case Study:

LangerChen

A Sustainable Journey from China to Europe

Company Snapshot

Location: Tutzing, near Munich

Year founded: 2008, first LangerChen collection in 2013

Year of GOTS certification: 2014 and 2021

Number of employees: 110 employees in China and 10 in Tutzing

Types of products: Eco Outerwear Coats, Jackets and Accessories

Number or quantity of material or products produced: Every year we produce a spring/summer and an autumn/winter collection according to customer orders. We have around 250 customers in central to northern Europe and Canada.

How much of it (material/products) is GOTS certified: In the actual spring/summer collection, 3 out of 34 models are GOTS certified, in the fall/winter collection it is 11 out of 45 models

Where can consumers find your products? www.langerchen.com

and in numerous shops that sell our products:

https://www.avocadostore.de

https://loveco-shop.de

https://rrrevolve.ch/stores,

and from spring 2024

https://www.manufactum.de

A Commitment to Fairness and Eco-Fashion

LangerChen, founded by Miranda Chen and Philipp Langer in 2008, has redefined "Made in China" in the fashion industry. Its story began with the establishment of Jiecco, a textile manufacturer in China. The vision was clear: to create environmentally friendly and ethically produced textiles in a region often associated with mass production and subpar working conditions.

That passion for fashion and an expertise in fabric development were the foundation for LangerChen's eponymous fashion label emerged in 2013. Since then, it has become synonymous with fairness, quality, and timeless style.

Eco-Fashion: Where Style Meets Ethical Production

Combining organically certified natural fibres with technical membranes LangerChen creates weather resistant eco-outerwear that blends fashion with function. Its commitment to social responsibility, sustainable practices, and the environment is evident in every aspect of operation. LangerChen manages the entire production process, from fabric to finished jacket, in its own GOTS-certified facility, located just an hour from Shanghai.

In the LangerChen factory in China, the company has established not only a transparent supply chain but a close-knit team. With a strong focus on employee welfare, company owners and managers know each of their 110 long-term employees personally. LangerChen pays fair wages, ensuring that good working conditions are maintained. Going a step further, it organises daily transportation for the team, fostering an inclusive and sustainable working environment.

GOTS: Elevating Sustainability Standards

In 2014, LangerChen’s production site achieved GOTS certification, marking a significant milestone in its journey. The choice of GOTS reflects its commitment to the highest standards for environmental and social practices. In 2021, European distribution completed the certification of the supply chain in order to provide customers with the security of a fair and sustainable product with the GOTS seal.

Aligning with the strict criteria of GOTS has had an influence throughout the company’s operations. Not only has it enforced measures to maximise resource conservation and minimise its carbon footprint, its entire production process revolves around the GOTS principles. That means ensuring that it produces only what is needed, reduces excess quantities, providing an in-house repair service for garment longevity, and decreasing plastic packaging. Even transportation is optimised for minimal CO2 emissions.

In the fashion industry, where change is often slow, LangerChen's commitment to responsible production sets the bar high, demonstrating that 'Made in China' can signify ethical practices, quality, and timeless fashion.

Case Study: Living Crafts

GOTS Case Study:

LIVING CRAFTS

Pioneering Sustainable Fashion

Living Crafts

Since its founding in 1985, Living Crafts has been at the forefront of sustainable fashion, playing a pivotal role in shaping the industry. With a humble beginning in a garage producing organic socks, the company has evolved into one of the most prominent suppliers of environmentally friendly textiles. Living Crafts is dedicated to providing high-quality, durable, and sustainable clothing and home textiles that resonate with the values of consumers who care about their environmental impact.

Local to Global Reach

Living Crafts is based in the Bavarian town of Selbitz, where product development, administration, and warehousing take place. Its products, however, are sourced from around the world, including countries such as Lithuania, Turkey, India and Germany. In a world where fashion is often seen as disposable, Living Crafts stands out by emphasising quality and durability. The company's philosophy centres around offering high-quality clothing that endures beyond a single season.

Ecological Commitment

Living Crafts is committed to offering alternatives that customers can trust. The company prioritises sustainability through its GOTS-certified products, membership in the Fair Wear Foundation, and CO2 compensation partnerships with renowned organisations. These efforts ensure that the environmental and social aspects of the supply chain align with the company's core values.

Making Every Day Special

Living Crafts aims to make every day special for its customers. The company focuses on fashion trends that meet the demands of daily life, offering versatile designs that can be combined into various outfits. Additionally, the company's home textiles are designed to create a sense of well-being in one's living space, making customers feel good every day, whether at work, leisure, or special occasions.

Affordable Sustainability

Living Crafts adheres to the principle of offering high-quality products at affordable prices. The company believes that sustainable clothing should be accessible for everyday wear, and this affordability plays a crucial role in driving change from the exception to the rule in the fashion industry.

GOTS Certification and Sustainability

With sustainability as the guiding principle of operations for Living Crafts, GOTS certification not only reinforces the company’s own commitment to responsible production, but it also has enhanced the credibility of Living Crafts with consumers. It reinforces the alignment of GOTS and the company's values, serving as a testament to its commitment to responsible sourcing.

During the certification process, Living Crafts encountered the challenge of formalising practices that were already ingrained in its sustainable operations. The company needed to put these practices in writing to facilitate internal and external communication. For example, it introduced a Code of Conduct that all suppliers must sign, as well as meticulously documenting various aspects of the operation.

Case Study: Naturepedic

Case Study

Naturepedic

Naturepedic

Company Snapshot

Location: Headquartered at 16925 Park Cir Dr, Chagrin Falls, OH 44023 with 20+ organic mattress galleries from coast to coast

Years in operation: 20 (founded in 2003)

Year you received GOTS certification: 2009

Number of employees: 100+

Types of products you make: GOTS certified organic mattresses and bedding for babies, kids, adults and pets

Units produced monthly: More than 10,000 GOTS-certified items produced monthly

Where can consumers find your products: Online at Naturepedic.com , as well as through our many retail partners and affiliates

How it all began...

In 2003, Board Certified Environmental Engineer Barry A. Cik set out to find a crib mattress for his first grandchild. To his surprise, he couldn't find a single option that met his standards: made without questionable chemicals, harmful waterproofing agents, potential allergens, and hazardous flame retardants. Determined to provide a safer sleep environment for his family and others, Barry, joined by his sons, Jeff and Jason, laid the foundation for Naturepedic, pioneering the organic mattress movement. Today the company offers certified organic sleep solutions for individuals of all ages, including babies, kids, adults, and even pets.

Pioneering Organic Sleep

Naturepedic has always been more than just a mattress company. It has dedicated itself to the pursuit of a healthier, restorative, and organic sleep. Since its founding, the company has specialised in creating handcrafted GOTS-certified organic mattresses that do not contain the harmful materials found in conventional mattresses, such as polyurethane foam, vinyl/PVC, PFAS, pesticides, GMOs, toxic VOCs, or other harmful substances. Instead, it sources and creates its products using healthier alternatives like GOTS-certified organic cotton, GOTS-approved (GOLS- or FSC®-certified) latex, FSC®-controlled wood, PLA batting derived from non-GMO sugarcane, and in-house manufactured encased coils without any glues or adhesives.

Trailblazers in Organic Mattresses

Naturepedic stands at the forefront of the organic mattress movement. It is renowned as the most certified and awarded organic mattress brand in the industry, testifying to its unwavering commitment to quality. When Naturepedic started in 2003, however, the term "organic mattress" lacked a clear definition for most people. Globally, GOTS has played a pivotal role in defining what an organic mattress truly is, differentiating it from conventional, non-organic options. Naturepedic's commitment to GOTS standards has not only legitimised the brand but has also positively influenced the mattress and bedding industry, establishing GOTS as the worldwide standard for organic mattresses.

For Naturepedic, the GOTS certification is a testament to the exceptional standard its products adhere to, setting them a cut above the rest in the market. As founder, Barry Cik says, “There is no way to trust organic claims unless those claims are validated by the GOTS certification program.”

It's more than just a badge – it's a seal of trust and quality that transcends marketing claims, providing concrete assurance to customers. With every Naturepedic mattress, one is not just investing in superior comfort but in a product with a verified higher standard of organic integrity and craftsmanship. GOTS certification narrates a story of value, trust, and uncompromised quality.

What sets Naturepedic apart is not just its products but two important guiding principles:

• It’s not organic unless it’s GOTS certified organic.

• Chemicals are guilty until proven innocent.

A Commitment to Sustainability

The company isn't just in the business of selling organic mattresses; it's comprised of dedicated environmentalists. Recently, it adopted a new kraft paper roll-packing system, ensuring that all its mattresses, comfort layers, and toppers are wrapped in fully recyclable kraft paper. This switch is a testament to the company's commitment to sustainability, keeping over 55,000 pounds of plastic out of landfills annually.

With over two decades of expertise in crafting organic mattresses and sleep accessories, Naturepedic is now poised for expansion into a broader range of organic home and lifestyle products, including duvets, throw blankets, bathrobes, towels, furniture, and more. Throughout this forward-looking journey, Naturepedic's commitment to the GOTS standard remains unwavering, defining what it means to be "organic" and providing customers with peace of mind.

Case Study: Original Favorites

GOTS Case Study:

Original Favorites

Company Snapshot

Location: Denver

Years in operation: 8

Year you received GOTS certification: 2023

Number of employees: 6

Types of products: Wholesale T-shirts and Fleece Knitwear

Where can consumers find your products: https://originalfavorites.com/

Original Favorites specialises in crafting luxury wholesale blank garments tailored for various businesses seeking premium blanks for customising and decorating. The company's product line encompasses an array of high-quality blanks, including sweats, t-shirts, and knit beanies. These garments are exclusively made from the finest materials such as Supima® cotton, Cashmere Merino Wool, and organic cotton fibres.

Sustainability Initiatives

Established in 2016, Original Favorites embarked on a mission to create luxury wholesale blank garments that combine an unwavering commitment to quality with a profound dedication to environmentally sustainable and ethically sound manufacturing. The journey commenced with a meticulous evaluation of raw materials, prioritising the utilisation of the world's finest natural fibres. An essential aspect of the company’s commitment to environmental stewardship includes considering both the land and the people involved in the cultivation process. This emphasis on ethical practices and sustainability spans the entire production process, ultimately guiding every decision.

Why GOTS Certification?

GOTS certification impeccably aligns with the company's core values and its enduring commitment to responsible and sustainable practices. Certification also assures the company and its clients that the strict and rigorous requirements of the Standard have been successfully undertaken. GOTS certification and label on final products acts as a significant value addition, attracting clients due to the authenticity, transparency, and credibility it offers.

Looking Ahead

Original Favorites aims to concentrate on educating and encouraging clients to demand proof from their suppliers, emphasising the importance of responsible and sustainable practices within the industry. Its recent GOTS certification serves as a testament to the company's unwavering commitment to quality, sustainability, and transparency, firmly establishing a high standard within the luxury wholesale blank garment sector.

Case Study: Saitex

GOTS Case Study:

Saitex

A Sustainable Vision for Denim Manufacturing

Saitex, headquartered in Vietnam, has emerged as a pivotal force in the global denim industry since its establishment in 2012. With the capacity to produce an impressive 20,000 pairs of jeans per day, the company's true distinction lies in its innovative approaches to denim manufacturing and a profound commitment to social equity. Amidst the fashion industry's often contentious sustainability and environmental concerns, Saitex's narrative takes centre stage, focusing on groundbreaking strategies and unwavering dedication to its employees and the local community.

A Green Beacon in Denim Manufacturing

Saitex's LEED-certified facility redefines the standard for clean water practices. They recycle an astounding 98% of the water used, a remarkable feat in an industry notorious for water wastage. Traditional denim manufacturers waste up to 1,500 litres of water per pair of jeans with inefficient practices and outdated technology. In contrast, Saitex employs efficient jet washing machines, losing just 0.4 litres of water to evaporation. Additionally, on-site rainwater collection pools minimise water consumption impact. Saitex's five-step filtration process purifies water, rendering it so clean that it's drinkable.

Green Energy

Saitex is committed to renewable energy resources, particularly solar power, a dedication that has reduced annual energy usage by 5.3 million kilowatt-hours and cut CO2 emissions by nearly 80 percent. They've taken a page from the past, air drying jeans with recycled factory machinery air, a sustainable alternative to the inefficient traditional dryers that used excessive electricity. To offset remaining emissions, they plant trees, contributing to a greener world.

Clean Waste: All wastewater treatment plants create a toxic byproduct called sludge. But at SAITEX, the sludge is extracted and shipped to a nearby brick factory. Mixed with concrete, the toxic material can no longer leech on the environment, and the resulting bricks are used to build affordable homes for the people in need.

Empowering Communities Through Responsible Business Practises

Saitex firmly believes in harnessing the power of business as a force for good, aiming to create a healthier, more equitable world. Their endeavours include:

Empowering the Next Generation: Saitex supports three orphanages housing 800 children. These children are offered training and employment opportunities at Saitex when they turn 18.

Food for Good

In collaboration with Everlane, Saitex has implemented hydroponic and clean farming systems, providing healthy food for the community while generating jobs that promote social interaction and employment with equal pay for vulnerable groups.

Supporting Gender Equality: With 58% of their workforce comprising women, Saitex actively promotes gender equality, with many women holding key positions within the company.

One-of-a-Kind Production Line: The Rekut production line is a platform for differently-abled individuals to receive training and support for sustainable employment, with an ambitious goal of creating 1,000 jobs and avoiding 1,000,000 kg of landfill waste by 2025.

Saitex's vision for sustainability and social equity is about more than just denim; it's about shaping a future where business serves as a force for good. Their innovations in water and energy conservation, waste management, and commitment to supporting communities demonstrate that it's possible to transform even the most polluting industries into champions of sustainability and social equity. Saitex invites us to see abilities, not disabilities, and to believe in a world where affordable, clean food is a basic human right, all while leaving a greener, cleaner footprint on the planet.

Case Study: Schoeller Spinning Group

GOTS Case Study:

Shoeller Spinning Group

Crafting Sustainability and Excellence in Yarn Production

The Schoeller Spinning Group, a global leader in yarn production with a strong focus on worsted yarn, understands that true innovation is born from collaboration. By working closely with its customers, the company creates superior solutions.

Yarn that Transcends Quality

The key to impeccable textiles in the realms of fashion, sports, and technical applications lies in the primary material - yarn. Schoeller's product strategy revolves around high-value, functional yarns. Its commitment to innovation keeps it at the forefront of industry trends.

Eco-Conscious Evolution

The shifting landscape of climate change has sparked a transformation in environmental consciousness. Consumer behaviour is evolving, placing a premium on sustainability and collections tailored to specific audiences. Schoeller acknowledges this shift and adheres to stringent ecological guidelines throughout its production and procurement processes.

Schoeller’s laboratories are hubs of continuous development and optimisation, focusing on greener processes and products. One of the company’s newest achievements, the EXP wool treatment process sets a sustainability benchmark. The chlorine-free process uses less resources than conventional processes and is carried out reliably at the company’s European manufacturing site, meaning that it is a truly holistic sustainable innovation.

Satisfaction Beyond Expectations

Schoeller prides itself on satisfying customer needs and more. Its commitment extends to providing a reliable supply service, maintaining a readily available stock, and offering a wide range of innovative yarns. It stands ready to support the realisation of ideas and the achievement of objectives.

This shared success, underpinned by sustainability and excellence, safeguards not only the future of the company but also the livelihoods it supports. Schoeller Spinning Group is weaving a tapestry of sustainability, innovation, and customer satisfaction, benefitting all involved.

Eco-Conscious Evolution

...

Case Study: SNOCKS

GOTS Case Study:

SNOCKS

CRAFTING A SUSTAINABLE FUTURE

GOTS and SNOCKS - A Synergy of Values

Family business or big player? Socks or underwear? Stylish or simple? At SNOCKS, the answer is: definitely everything! This e-commerce company started with socks on Amazon and has since made a name for itself with basic and sportswear. The most important pillars have never changed: quality, comfort, and responsibility.

Transparency and Integrity as Cornerstones

SNOCKS is aware of the challenges in the production industry and understands that every manufacturing process leaves an ecological footprint. The company does not hastily label itself as 'sustainable', but instead chooses the path of transparency and honesty. It is constantly looking for ways to reduce ecological impacts and improve working conditions along the supply chain. And SNOCKS takes its customers along on this journey.

The Alliance between SNOCKS and GOTS

Through its partnership with GOTS, SNOCKS ensures that the processing of organic cotton meets the highest ecological and social standards. SNOCKS commits to improving working conditions for everyone involved in the supply chain. And the customers are informed about it. Because SNOCKS communicates its efforts, progress, and also challenges in a transparent and easily understandable way.

SNOCKS' Objectives: ambitious and clear

- Manufacturing timeless basics to reduce overproduction.

- Promoting fair working conditions.

- Using more environmentally friendly materials.

- Committing to transparent and clear communication.

SNOCKS and GOTS work hand in hand. Not just to show how things can be done differently, but to demonstrate how they can be done better. Together, they stand for a change that goes beyond mere concepts – it's about actions and about truly embodying values like quality, comfort, and honesty.

Case Study: Sunflag Tanzania

GOTS Case Study:

Sunflag Tanzania

A Commitment to Sustainability and Social Equity

Sunflag Tanzania Ltd, a leading knitwear manufacturer, produces a diverse range of garments, including men's, women's, kids', and baby wear. With a monthly capacity of 600,000 units, Sunflag combines convenience with conscientiousness by offering in-house printing and embroidery services. But what truly sets Sunflag apart is its dedication to sustainability and social equity.

A Legacy of Excellence

Established in 1965, Sunflag has been a pioneer in the textile and clothing industry. It operates as a fully integrated company in Arusha, Tanzania, employing over 2700 individuals and serving international markets.

Rooted in a history of vision and innovation, Sunflag's founder, Mr. Satya Dev Bhardwaj, established the first knitting factory in Kenya in the 1930s. Sunflag stands as a testament to unwavering commitment to the best raw materials, cutting-edge machinery, skilled manpower, and top-tier customer service. Over the past seven decades, the Sunflag Group has expanded its operations globally, with manufacturing facilities and offices in various countries.

A Vertical Factory

Sunflag operates as a vertical factory, consolidating all production processes within one location. This approach minimises the environmental impact of its garments. To ensure that its manufacturing is as eco-friendly as possible, all water used in the production process is meticulously treated by an effluent treatment plant. This ensures the water is free from dyes or harmful chemicals that could damage the ecosystem.

The Source of Organic Cotton

Sustainability and equality are central to Sunflag's operations in Africa. The company partners with organisations committed to supporting local farmers and businesses. All of Sunflag's cotton is rain-fed, reducing water consumption compared to irrigation-dependent regions. To transport the cotton from the farm to the ginnery, ox and cart are used, further lowering carbon emissions compared to traditional truck transportation in other countries.

Promoting Sustainable and Fair Farming

By championing sustainable and equitable farming practices, Sunflag ensures the highest quality of organic African cotton while investing in the future of communities across the Singida, Simiyu, and Tabora regions of Tanzania. The company’s support enables these regions to flourish.

Social Accountability

Sunflag Tanzania is deeply committed to social accountability, ensuring that all operations uphold national and international laws, and respect collective bargaining agreements. Its dedication extends to all parties involved in Its business, ensuring open and comprehensive communication. Through continuous monitoring, training, and improvement, Sunflag maintains and improves its Social Accountability Management System.

Step 5:

Prepare for the on-site audit

Prepare for the on-site audit

The Certification Body will inform you about the implementation and schedule an audit. It is important to prepare all necessary documentation and records for review, about which you will be informed by your Certification Body ahead of time. In case any non-compliances with the Standard are detected, these will be assessed and a timeline for correction will be provided to you.

Step 6:

Receive your GOTS Scope Certificate

Receive your GOTS Scope Certificate

Once you receive your GOTS Scope Certificate, you can leverage it to showcase your commitment to sustainable and ethical textile production. Your company will be found in the GOTS public database.

Contact

Please use the form below to contact us.

You may also email a GOTS Representative directly from the country nearest you here.

For any information about abuses of the GOTS logo or quality assurance system, please fill out the complaint form.

Write a message

*mandatory

Downloads

-

English

- Standard and Manual

- GRTS Draft 1.0 for Public Consultation-July 2025

- GRTS Manual Draft 1.0 for Public Consultation - Clean - July 2025

- GOTS Due Diligence Handbook for Auditors_ v1.0

- Manual for the Implementation of GOTS Version 7.2

- Change Log Manual for the Implementation of GOTS 7.2

- Change Log_ GOTS Due Diligence Handbook for Certified Entities v1.0 to 1.1

- GOTS Due Diligence Handbook for Certified Entities 1.1

- Q&A Guideline for the Transition to a New GOTS Version v. 2.0

- GOTS Version 7.0 (March 2023)

- Guidelines for the new structure of GOTS 7.0

Previous Versions:

- Manual for the Implementation of GOTS Version 7.1

- Change Log Manual for the Implementation of GOTS 7.1

- Change log GOTS 6.0 to GOTS 7.0

- GOTS Due Diligence Handbook for Certified Entities 1.0.pdf

- Change log manual for the implementation GOTS 6.0 to GOTS 7.0

- Manual for Implementation Version 7.0 (March 2023)

- GOTS Version 6.0 (March 2020)

- GOTS Version 5.0 (2017)

- Manual for Implementation Version 6.0 (March 2020)

- Manual for Implementation Version 5.0 (2017)

- Summary of relevant Changes from GOTS 5.0 to 6.0

- Guidance Note for Implementation of GOTS Version 6.0

- GOTS Version 4.0 (2014)

- Manual for Implementation Version 4.0 (2014)

- GOTS Version 3.0 (2011)

- Manual for Implementation Version 3.0 (2011)

- GRTS Draft 1.0 for Public Consultation-July 2025

- Licensing and Labelling

- Retailer Declaration for the use of GOTS Signs v 3.0 Aug 2025

- Revision of GOTS fees March 2024

- Conditions for the Use of GOTS Signs Vers. 3.1 (18 Oct 2021)

- Change Log Conditions Use GOTS Signs Vers. 3.1 (18 Oct 2021)

- Labelling Release for GOTS Goods

- Labelling Release for GOTS Additives

- Labelling Release GOTS Goods (word document)

- Labelling Release GOTS Additives (word document)

Previous Versions:

- Retailer Declaration for the use of GOTS Signs v 3.0 Aug 2025

- GOTS Annual Reports

Previous Versions:

- GOTS Annual Report 2023

- GOTS Annual Report 2022

- GOTS Annual Report 2021

- GOTS Annual Report 2020

- GOTS Annual Report 2019

- GOTS Annual Report 2018

- GOTS Annual Report 2017

- GOTS Annual Report 2016

- GOTS Annual Report 2015

- GOTS Annual Report 2014

- GOTS Annual Report 2013

- GOTS Annual Report 2012

- GOTS Annual Report 2011

- GOTS Annual Report 2023

- Certificate Policies and Templates

- Certification and Operating Parameters for GOTS Certified Gins V 2.1 - Dec 2025

- Procedure For Certification of CSCS v 1.0

- GOTS Geographic Classification Version 1.1

- Materials, Processes & Products Classification Vers. 1.1 (Sept. 2024)

- GOTS Advisory on Accessory Approval under GOTS

- Provision for issuance of GOTS transcation certificates for retail goods (4 Sept 2023)

- GOTS measures for the regions affected in the Southeast Turkey and surrounding regions (8 Feb 2023)

- Advisory on Policy for the Issuance of Transaction Certificates v. 3.0 (5 Sept 2022)

- List of laboratories that can carry out qualitative GMO testing (14 July 2023)

- Guidelines to Virtual Audits Related to COVID-19 v. 5.0 (5 Jan 2022)

- Policy for the Issuance of Scope Certificates v. 3.0 (6 Oct 2021)

- Policy for the Issuance of Transaction Certificates v. 3.0 (6 Oct 2021)

- Scope Certificate Template v. 3.0 (6 Oct 2021)

- Transaction Certificate Template v. 3.0 (6 Oct 2021)

- Changelog for VA guidelines v. 2.0 to 3.0 (5 March 2021)

- Guidance Note LETIS Termination Effects V. 1.1 (Dec 2020)

- Policy for Change or Migration of Certification Body V. 1.1 (Nov 2020)

- Policy for Issuing Letters of Approval for GOTS Additives (Sep. 2020)

- Template for Issuing Letters of Approval for Colourants/Textile Auxiliaries (Sep. 2020)

- Template for Issuing Letters of Approval for Accessories (Sep. 2020)

Previous Versions:

- Certification and Operating Parameters for GOTS Gins v2.0 - Sep 2025

- Certification and Operation Parameters for GOTS Certified Gins v. 1.1 (4 Nov 2022)

- Certification and Operation Parameters for GOTS Certified Gins v. 1.0 (4 Oct 2022)

- Materials, Processes & Products Classification Vers. 1.0 (May 2021)

- GOTS Geographic Classification Vers. 1.0 (6 October 2021)

- GOTS Measures COVID-19 v. 4.0 (27 April 2021)

- Virtual Audits v 3.0 (5 March 2021)

- Virtual Audits v 2.0 (23 June 2020)

- Scope Certificate Policy V. 2.1 (Dec. 2019)

- Scope Certificate Template V. 2.1 (Dec. 2019)

- Annex 2 to Scope Certificate Policy (Sep. 2019)

- Transaction Certificate Policy V. 2.1 (Dec. 2019)

- Transaction Certificate Template V. 2.1 (Dec. 2019)

- Policy for Issuing Transaction Certificates (2017)

- Transaction Certificate Template (2017)

- Virtual Audits v 1.0 (7 April 2020)

- GOTS Measures COVID19 Update

- Changelog to VA guidelines v.1.0 to 2.0

- GOTS Measures On COVID 19

- Policy for Issuing Scope Certificates (2016)

- Scope Certificate Template

- Policy for Approval Letters (2014)

- Template for Issuing Letters of Approval (2014)

- Certification and Operating Parameters for GOTS Certified Gins V 2.1 - Dec 2025

- Revision Process

- GOTS V 8.0 2nd Revision Draft

- Manual for the Implementation of GOTS V 8.0 2nd Revision Draft

- 1st Public Consultation Inputs - SRC Decisions - GOTS 8.0

- Template for comments - 2nd revision drafts

- Consolidated list of inputs received during the first consultation period with decisions by the GOTS SRC

- Changelog for 2nd revision draft (from 1st revision draft) - Manual

- Changelog for 2nd revision draft (from 1st revision draft) - Standard

- Implementation Manual v 7.0 - 2nd revision draft

- GOTS v 7.0 - 2nd revision draft

- GOTS 7.0 Revision Draft v. 1.0

- Change Log Revision Draft v.1.0 GOTS 7.0

- Implementation Manual 7.0 Draft v. 1.0

- Change Log Revision Draft v.1.0 Implementation Manual 7.0

- Template for proposing changes Revision 7

- GOTS Stakeholder Identification v-1.0 Nov 2021

- Standard Setting Procedure v-1.0 Nov 2021

- ToR Standard Revision Committee v-1.0 Nov 2021

- GOTS V 8.0 2nd Revision Draft

- Governance

- Advisory on Certification

- Position Papers

- Requirements for Certification Bodies

- Approval Procedure and Requirements for Certification Bodies Version 4.0

- Change Log - Approval Procedure and Requirements for Certification Bodies 4.0

- Approval Procedure and Requirements for Certification Bodies v. 3.0

- Change Log APRCB v. 2.0 to v. 3.0

- Moratorium on new Certification Bodies (pdf)

- GOTS Accreditation System for Certifiers

- Application Form for GOTS Accreditation

- Approval Procedure and Requirements for Certification Bodies Version 4.0

- Change or Migration of Certification Body

- Complaint Procedure

- GOTS Flyers

- GOTS Fact Sheets

- Why GOTS - Your Key to Achieving Compliance

- Why GOTS - Control of Chemicals in GOTS Goods

- Why GOTS - How Official Bodies, Organisations and Institutions support the Global Organic Textile Standard

- Why GOTS - How Companies Benefit with GOTS Certification

- Why GOTS - How Consumers Benefit from GOTS

- Why GOTS - How GOTS Meets Legal Requirements and Demands of NGOs

- Why GOTS - Your Key to Achieving Compliance

- Simple Show Clip

- Info poster on Organic Wool

- Security Advice Adverts

- Security Advice Adverts for Retailers: 210x99 GOTS

- Security Advice Adverts for Retailers: 105x297 GOTS

- Security Advice Adverts for Retailers: 105x148 GOTS

- Security Advice Adverts for Consumers: 210x148 GOTS

- Security Advice Adverts for Consumers: 210x99 GOTS

- Security Advice Adverts for Consumers: 105x297 GOTS

- Security Advice Adverts for Consumers: 105x148 GOTS

- Security Advice Adverts for Retailers: 210x99 GOTS

- Approved Consultants

- Derogations

- Standard and Manual

-

German / Deutsch

- GOTS Dokumente Deutsch

- Nutzungsbedingungen für die GOTS Zeichen v. 3.1 (Okt 2021)

- Liste der Änderungen - Nutzungsbedingungen GOTS Zeichen v. 3.1

Vorherige Versionen:

- Manual for the Implementation of GOTS Version 7.1 _DE

- GOTS Version 6.0 - Deutsch (2020)

- Manual for Implementation Version 6.0 / Manual für die Umsetzung (2020)

- Summary of relevant Changes from GOTS 5.0 to 6.0 / Liste der relevanten Änderungen 5.0 auf 6.0

- GOTS Version 5.0 - Deutsch (2017)

- GOTS Version 4.0 - Deutsch (2014)

- Manual for Implementation Version 4.0 (2014) / Manual für die Umsetzung 4.0 (2014)

- GOTS Version 3.0 - Deutsch (2011)

- Manual for Implementation Version 3.0 (2011) / Manual für die Umsetzung 3.0 (2011)

- Nutzungsbedingungen für die GOTS Zeichen v. 3.0 (Juli 2021)

- Liste der Änderungen v 2.0 - Nutzungsbedingungen GOTS Zeichen v. 3.0

- GOTS Licensing and Labelling Guide (2017; updated 2018) / Lizensierung- und Labelling Leitfaden (2017, aktualisiert 2018)

- GOTS Licensing and Labelling Guide (2016) / Lizensierung- und Labelling Leitfaden (2016)

- GOTS Licensing and Labelling Guide (2015) / Lizensierung- und Labelling Leitfaden (2015)

- Nutzungsbedingungen für die GOTS Zeichen v. 3.1 (Okt 2021)

- GOTS Flyers

- Anzeigen Sicherheitshinweise

- Sicherheitshinweis für Einzelhändler: 210x148 GOTS

- Sicherheitshinweis für Einzelhändler: 210x99 GOTS

- Sicherheitshinweis für Einzelhändler: 105x297 GOTS

- Sicherheitshinweis für Einzelhändler: 105x148 GOTS

- Sicherheitshinweis für Verbraucher: 210x148 GOTS

- Sicherheitshinweis für Verbraucher: 210x99 GOTS

- Sicherheitshinweis für Verbraucher: 105x297 GOTS

- Sicherheitshinweis für Verbraucher: 105x148 GOTS

- Sicherheitshinweis für Einzelhändler: 210x148 GOTS

- Simple Show Clip

- GOTS Dokumente Deutsch

-

French / Français

- Documentes en Français

Previous Versions:

- Manual for Implementation 4.0 (2014) / Manuel de Mise en Oeuvre 4.0 (2014)

- GOTS Version 4.0 - French (2014)

- Manual for Implementation 5.0 (2017) / Manuel de Mise en Oeuvre 5.0 (2017)

- GOTS Version 5.0 - French (2017)

- Manual for Implementation 6.0 (2020) / Manuel de Mise en Oeuvre 6.0 (2020)

- GOTS Version 6.0 - French (2020)

- Manual for Implementation 4.0 (2014) / Manuel de Mise en Oeuvre 4.0 (2014)

- Plus de Documents

- Simple Show Clip

- Documentes en Français

-

Italian / Italiano

-

Spanish / Español

- Documentos en Español

- Guidelines new structure GOTS 7.0_ES

- Change Log Manual for the Implementation of GOTS V7.0_ES

- Manual for the Implementation of GOTS V7.0 _ES

- GOTS 7.0 _ES

Previous Versions:

- Manual for Implementation (2011) / Manual para Implementacion (2011)

- GOTS Version 3.0 - Spanish (2011)

- Manual for Implementation (2014) / Manual para Implementacion (2014)

- GOTS Version 4.0 - Spanish (2014)

- Manual for Implementation (2017) / Manual para Implementacion (2017)

- GOTS Version 5.0 - Spanish (2017)

- Manual for Implementation 6.0 (2020) / Manual para Implementacion 6.0 (2020)

- GOTS Version 6.0 - Spanish (March 2020)

- Change Log GOTS 6.0 to 7.0_ES

- Guidelines new structure GOTS 7.0_ES

- Más Documentos

- Simple Show Clip

- Documentos en Español

-

Chinese / 中文

- 在中國的文件

- 认证机构变更或迁移政策V1.0_中文翻译

- GOTS Implementation Manual Version 7.0-Chinese/English GOTS7.0 实施手册英中双语版

- GOTS Version 7.0 - Chinese/English GOTS7.0 标准英中双语版

- Conditions for the Use of GOTS Signs Vers. 3.0 (23 July 2021)_Chinese

- Change Log Conditions Use GOTS Signs Vers. 3.0_Chinese

Previous Versions:

- Manual, Issue 1st March 2011-Chinese/English 全球有机纺织品标准实施手册(中文/英文)

- GOTS Version 3.0-Chinese/English 全球有机纺织品标准GOTS 3.0版本(中文/英文)

- Manual, Issue 1st March 2014-Chinese/English 全球有机纺织品标准实施手册(中文/英文)

- GOTS Version 4.0-Chinese/English 全球有机纺织品标准GOTS 4.0版本(中文/英文)

- Manual Version 5.0, Issue 1st March 2017-Chinese/English 全球有机纺织品标准实施手册(中文/英文)

- GOTS Version 5.0-Chinese/English 全球有机纺织品标准GOTS 5.0版本(中文/英文)

- List of Relevant Changes 6.0 -Chinese/English GOTS 6.0 版本变更列表

- GOTS Implementation Manual Version 6.0-Chinese/English 全球有机纺织品标准GOTS 6.0版本实施手册(中文/英文)

- GOTS Version 6.0 - Chinese/English 全球有机纺织品标准GOTS 6.0版本(中文/英文)

- 认证机构变更或迁移政策V1.0_中文翻译

- 宣传单格式仅供下载,请勿印刷。

- GOTS标签使用要求

- Simple Show Clip

- 在中國的文件

-

Japanese / 日本語

- 日本語ドキュメント

- > Change Log Conditions Use GOTS Signs Vers. 3.1_EN/JP

- > Conditions for the Use of GOTS Signs Vers. 3.1 (18 Oct 2021)_EN/JP

Previous Versions:

- > (Manual for Implementation) GOTS 3.0 実施マニュアル (2011)

- > GOTS バージョン3.0 (2011)

- > GOTS 3.0からGOTS 4.0への変更された事項のリスト (Relevant Changes from Veersion 3.0 to 4.0)

- > (Manual for Implementation) GOTS 4.0 実施マニュアル (2014)

- > GOTS バージョン4.0 (2014)

- > GOTS 4.0からGOTS 5.0への変更された事項のリスト(Relevant Changes from Version 4.0 to 5.0)

- > (Manual for Implementation) GOTS 5.0 実施マニュアル (2017)

- > GOTS バージョン5.0 (2017)

- > Relevant Changes GOTS 5.0からGOTS 6.0への変更された事項のリスト

- > (Manual for Implementation) GOTS 6.0 実施マニュアル

- > GOTS バージョン6.0

- > Licensing and Labelling Guide 2009 ライセンスとラベリングの手引き(2009版)

- > Licensing and Labelling Guide 2015 ライセンスとラベリングの手引き(2015版)

- > Licensing and Labelling Guide 2017 ライセンスとラベリングの手引き(2017版)

- > Change Log Conditions Use GOTS Signs Vers. 3.0_EN/JP

- > Conditions for the Use of GOTS Signs Vers. 3.0 (23 July 2021)_EN/JP

- > Change Log Conditions Use GOTS Signs Vers. 3.1_EN/JP

- インフォメーションフライヤー

- 認証書(SCとTC)について

- よくあるご質問

- GOTS 製品に関する注意事項

- Simple Show Clip

- 日本語ドキュメント

-

Danish / Dansk

-

Korean / 한국어

-

Turkish / Türkçe

- Türkçe Dokümanlar

- GOTS Broşürleri

- GOTS KULLANIM ŞARTLARI

- LOGO KULLANIM ŞARTLARI TÜKETİCİLER İÇİN 210x148

- LOGO KULLANIM ŞARTLARI TÜKETİCİLER İÇİN 210x99

- LOGO KULLANIM ŞARTLARI TÜKETİCİLER İÇİN 105x297

- LOGO KULLANIM ŞARTLARI TÜKETİCİLER İÇİN 105x148

- LOGO KULLANIM ŞARTLARI PERAKENDECİLER İÇİN 210x148

- LOGO KULLANIM ŞARTLARI PERAKENDECİLER İÇİN 210x99

- LOGO KULLANIM ŞARTLARI PERAKENDECİLER İÇİN 105x297

- LOGO KULLANIM ŞARTLARI PERAKENDECİLER İÇİN 105x148

- LOGO KULLANIM ŞARTLARI TÜKETİCİLER İÇİN 210x148

- Simple Show Clip

econews

Reach out to the GOTS Representative in your region

GOTS has appointed several representatives who operate in a global network to promote GOTS in their respective regions and around the world.

Find the Representative in your region

Featured on the GOTS Youtube Channel:

Faces From Field to Fashion is a behind-the-scenes journey to the heart of the Global Organic Textile Standard (GOTS), and an introduction to the sights, sounds, and faces behind every GOTS product. Representing more than 4 million employees working in GOTS certified facilities around the world, eight individuals give us a glimpse into their lives and tell us how they have been impacted by GOTS in unscripted and candid video portraits. Visit global-standard.org/faces for more information. Your choice matters: Say no to Greenwashing. Say yes to GOTS.

Follow Us on LinkedIn & Instagram

Feedback for Reclaim Trust - GOTS UK Roundtable

Thank you for attendance at the GOTS & Sustainable Fashion Week Reclaim Trust Conference and Roundtable.

We hope you enjoyed the day!

Please submit your feedback using this brief form:

General Terms and Conditions (GTC) for GOTS Shop-Finder

-

Definitions

- „Global Standard“ shall mean the Global Standard gemeinnützige GmbH, Rotebühlstr. 102, 70178 Stuttgart, Germany.

- “GOTS” refers to the Global Organic Textile Standard. A worldwide textile processing standard for organic fibres, including ecological and social criteria. The full text of the GOTS can be found at https://global-standard.org/downloads.

- “GOTS Marks” are the trademarks owned worldwide by Global Standard.

- “GOTS Products” are products that are properly certified and labelled in accordance with the Global Organic Textile Standard and corresponding regulations for the use of GOTS Marks, which can be found at https://global-standard.org/downloads.

- “GOTS Shop-Finder” is a publicly accessible database published by Global Standard on their website, which provides information about retailers that offer GOTS Products to consumers and the general public.

- “Retailer for GOTS Products” is a retailer that offers GOTS Products in accordance with these GTC.

- “Contractor” is an entrepreneur entering into a contract about a listing in the GOTS Shop-Finder with Global Standard.

-

Scope of GTC

- These GTC for the GOTS Shop-Finder apply exclusively between Global Standard and the Contractor; opposing or from these GTC deviating conditions of the Contractor are not recognized by Global Standard, unless Global Standard has expressly agreed to their validity.

- These GTC only apply in regard to a listing of the Contractor in the GOTS Shop-Finder.

- Global Standard is entitled to make reasonable adjustments to these GTC from time to time in case of a legitimate interest on our part. Such a legitimate interest may be changes in the law, changes in case law or changes in economic conditions. Global Standard will inform the Contractor at least 30 calendar days before the planned changes to the GTC shall come into force via E-Mail, about the specific changes and when they shall come into force. The Contractor may object within a period of 30 days to the changes via E-Mail. If the Contractor does not object to the changes these will come into force to the date Contractor was informed about. Should the Contractor object to the changes in the GTC, the contract shall be continued under the previous conditions unless a continuation under the previous conditions is not deemed reasonable for us. In this case we are entitled to terminate the contract with the Contractor.

-

Subject of the contract

- The subject of the contract is a listing of the Contractor as a Retailer of GOTS Products in the GOTS Shop-Finder for the duration of the contract for a fee to be paid by Contractor.

- The listing contains the name and the address of the Contractor. Any additional information the Contractor can and may provide for the GOTS Shop-Finder is only voluntary and not subject of the contractual obligations of Global Standard. Such options for additional information may be changed by Global Standard at any time.

-

Conclusion of Contract

- The listing in the GOTS Shoop-Finder is only offered to Retailers of GOTS Products.

- The offer of Global Standard to be listed does not constitute any binding offer, but an invitation to submit an offer by the Contractor.

- The Contractor's order for a listing is a binding offer to conclude a contract. Global Standard is entitled to accept this offer within two weeks. The acceptance will be under the condition that Contractor meets the requirements and obligations in para. 5. The Acceptance may be done by e-mail or other notification in writing or by issuing of an invoice.

-

Requirements and Obligations of the Contractor

- To be listed as a Retailer of GOTS Products in the GOTS Shop-Finder the Contractor guarantees that he meets the following requirements during the time of the contract:

- Contractor fulfills all applicable requirements of the GOTS and the conditions of use of GOTS Marks in the version applicable at the time.

- Contractor continuously offer GOTS Products for sale in the categories he is listed in the GOTS Shop-Finder.

- Contractor does not offer any products that infringe GOTS Marks or other intellectual property rights of Global Standard or use GOTS Marks for advertising purposes in an infringing way.

- Contractor does not use any reference to Global Standard or GOTS or GOTS Marks in a misleading or otherwise unlawful way.

- Contractor is obliged to provide correct information for the listing and keep his data in the GOTS Shop-Finder up to date for the duration of the contract.

- Contractor is obliged to pay the fee for the GOTS Shop-Finder listing.

- To be listed as a Retailer of GOTS Products in the GOTS Shop-Finder the Contractor guarantees that he meets the following requirements during the time of the contract:

-

Control and breach of obligations

- Global Standard may request documents from the Contractor to verify that the Contractor meets the requirements in para. 1.1., 5.1.2., 5.1.3. and 5.1.4. and to verify the information in the listing as provided by the Contractor. Upon such request Contractor will provide such documents (e.g. transaction certificates of the GOTS products, pictures of Contractor’s store or order forms that clearly show GOTS products are being offered) without undue delay.

- If Global Standard is informed about or becomes otherwise aware of a possible violation of the Contractor’s obligations under these GTC, Global Standard will investigate such possible violation. Unless violation claims against the Contractor are obviously baseless, Global Standard may block the listing of the Contractor in the GOTS Shop-Finder, until such investigations are concluded. The Contractor can accelerate such investigations by providing Global Standard with any requested information to resolve the allegations.

-

Warranty

- We warrant an availability of the GOTS Shop-Finder of 24 hours per day within our responsibility.

- Necessary scheduled maintenance shall be excluded from the availability of the GOTS Shop-Finder pursuant to para. 1.. Scheduled maintenance is work that is carried out for the purpose of technical adaptation, guarantee of function and interoperability, technical development and other changes to the GOTS Shop-Finder and the IT-Systems the GOTS Shop-Finder requires.

- Beside the scheduled maintenance according to para. 2 the availability of the GOTS Shop-Finder according to para. 7.1 can be limited by unplanned and unforeseen downtimes. These are times, in which by unplanned and unforeseen events, which Global Standard does not have to represent, like such force majeure, interruption of the power supply, hardware and software errors, technical problems in the data lines which impair the further operation of the GOTS Shop-Finder, the GOTS Shop-Finder is not available.

- In the event that the GOTS Shop-Finder is not available for more than one hour at a time due to scheduled maintenance, Global Standard shall inform the Contractor about the duration of the unavailability. Information about scheduled maintenance may also just be displayed on the website of the GOTS Shop-Finder. The same applies if the GOTS Shop-Finder is unavailable for more than one hour at a time due to unplanned and unforeseen downtime.

-

Intellectual Property

- These GTC and a listing in the GOTS Shop-Finder does not grant the Contractor any rights to use GOTS Marks or other intellectual property including copyrights of Global Standard.

- The Contractor may therefore not use the GOTS Marks or other intellectual property including copyrights of Global Standard unless expressly otherwise entitled to by Global Standard in accordance with the GOTS and the corresponding regulations.

- The Contractor warrants that the information provided by the Contractor does not infringe any third-party rights (e.g. trademarks, copyrights). The contractual partner indemnifies Global Standard against any claims of third parties which are asserted against Global Standard on the basis of the information provided by the Contractor on first demand.

-

Prices, payment, due date and default (as of July 2023, the GOTS Shop-Finder is free)

- The annual fee for the GOTS Shop-Finder is to be paid in full without deductions in advance for the respective term.

- The annual fee does not include Value Added Tax (VAT), which will be added to the fee if applicable.

- Payment is due upon receipt of the invoice or statement of account.

- Global Standard is entitled to send invoices exclusively by electronic means, provided that they comply with the requirements of German tax law.

- As a matter of principle Global Standard accept only the methods of payment that are listed in the order procedure or otherwise stated on the website or the invoice.

-

Term and Termination

- The term of the contract is 1 year.

- If neither Global Standard nor the Contractor don’t terminate the contract up to 2 weeks before the end of the respective contract term, the contract shall be extended by another year.

- The right to extraordinary termination shall remain unaffected.

- Global Standard shall in particular be entitled to extraordinary termination without notice if:

- the Contractor is more than 14 days in arrears with a due payment and has been reminded by Global Standard at least once.

- the Contractor violates his obligations or no longer meets the requirements in para. 5.

-

Limitation of liability

- We are liable without limitation for intent and gross negligence. In the case of non-intentional acts, liability is limited to the damage typically foreseeable at the time of conclusion of the contract. In the event of slight negligence, we shall only be liable in the event of a breach of material contractual obligations and limited to the damage typically foreseeable at the time of conclusion of the contract. This limitation shall not apply in the event of injury to life, limb or health.

- Insofar as liability for damages against us is excluded or limited, this shall also apply with regard to the personal liability for damages of our employees, representatives and vicarious agents.

- Except in the aforementioned cases, liability on our part is excluded.

-

Applicable Law; Place of Jurisdiction; Final Provisions

- The law of the Federal Republic of Germany shall apply.

- Legally relevant declarations and notifications by the Contractor with regard to the contract (e.g. setting of deadlines, termination) must be made in writing, i.e. in written or text form (e.g. letter, e-mail, fax). Legal formal requirements and further proof, in particular in case of doubts about the legitimacy of the declaring party, shall remain unaffected.

- If the Contractor is a merchant, a legal entity under public law or a special fund under public law, the place of performance and jurisdiction for all disputes shall be our registered office in Stuttgart. We are also entitled to take legal action at the Contractor’s general place of jurisdiction.

- Should individual provisions of these GTC be invalid, this shall not affect the validity of the remainder of the contract.

Read more …General Terms and Conditions (GTC) for GOTS Shop-Finder

GOTS Images

DOWNLOAD SINGLE IMAGES

GOTS Project: Controlled Supply Chain Scheme (CSCS)

GOTS Project:

Controlled Supply Chain Scheme (CSCS)

Unlocking Opportunities for Small-Scale Excellence in Organic Textiles

In the world of organic textiles, obtaining GOTS certification is a prestigious achievement, and one that can open the door to new business opportunities. But for small operators, the complexity and cost of this certification can be a barrier.

Empowering Small Operators